- W-97, MIDC, Anand Nagar, Ambernath (E), Dist: Thane, MH, INDIA, Pin: 421506

- marketing@fluidtecq.com

Knife gate valves (KGVs) play a critical role in various industries, including mining, wastewater treatment, pulp and paper, and chemical processing, food processing and conveying, packaging, dairy and pharma Industries, due to their ability to handle slurries, viscous fluids, and abrasive media effectively. . However, seven common mistakes can compromise their performance if users are not aware of them. By understanding and addressing these pitfalls, you can ensure optimal operation and longevity of KGVs in your systems.

Mistake: Selecting a knife gate valve unsuitable for the media (e.g., slurries, powders, or corrosive fluids) or operating conditions like high pressure or temperature, leading to premature failure.

How to Avoid: Match the valve to the application by reviewing Fluidtecq’s specifications for materials (e.g., stainless steel for corrosive media) and design (e.g., unidirectional or bi-directional). Consult Fluidtecq’s technical team to ensure compatibility with media, pressure, and temperature.

Mistake: Installing the valve upside-down or misaligned, causing leaks or gate jamming due to improper sealing or flow direction.

How to Avoid: Follow Fluidtecq’s installation guidelines, checking for flow direction markings on the valve body. Ensure proper alignment, especially for unidirectional knife gate valves, to match the pressure side with the valve’s design.

Mistake: Neglecting routine cleaning or inspection, leading to debris buildup, gate sticking, or seal wear, particularly in slurry or viscous applications.

How to Avoid: Adhere to Fluidtecq’s maintenance recommendations, including periodic cleaning of the gate and seat, inspecting seals, and lubricating moving parts. For slurry applications, flush the valve regularly to prevent clogging.

Mistake: Over-tightening the packing gland, which restricts gate movement and accelerates wear, or under-tightening, causing stem leaks.

How to Avoid: Adjust the packing gland per Fluidtecq’s specified torque settings to achieve a leak-free seal without hindering gate movement. Monitor for leaks during operation and make incremental adjustments as needed.

*Mistake*: Operating the valve partially open for flow control, which erodes the gate and seat due to high-velocity flow, reducing valve lifespan.

How to Avoid: Use Fluidtecq knife gate valves strictly for on/off service, as they are not designed for throttling. For flow regulation, opt for a valve type like a globe or control valve suited for throttling applications.

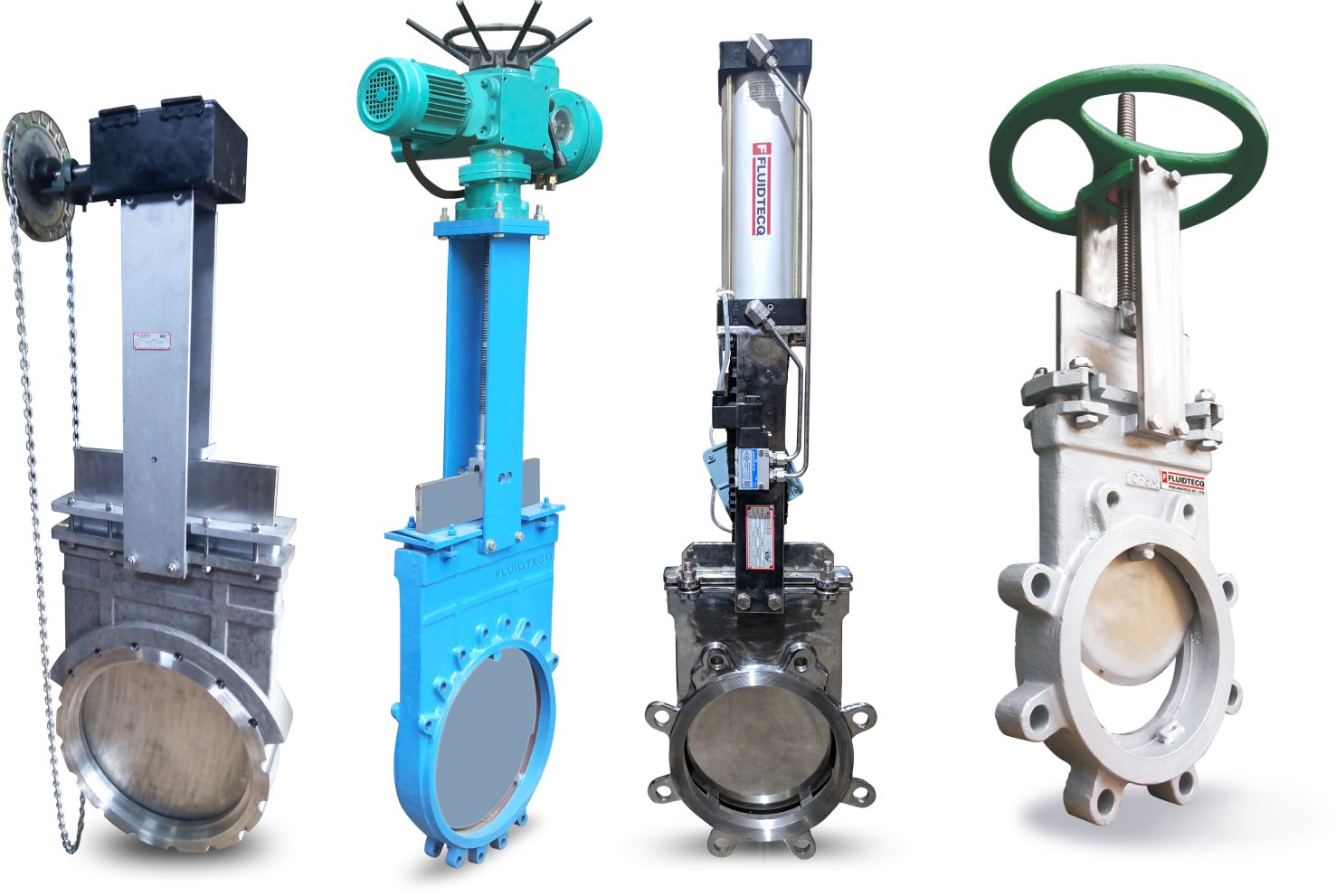

Mistake: Pairing the valve with an undersized or incompatible actuator (e.g., pneumatic or electric), resulting in insufficient force to cut through thick media or operate reliably.

How to Avoid: Ensure the actuator matches Fluidtecq’s valve torque requirements and media characteristics. Consult Fluidtecq for actuator sizing guidance to ensure compatibility, especially for pneumatic actuators commonly offered by the company.

Mistake: Failing to account for abrasive, sticky, or viscous media, which can cause gate sticking, seat damage, or poor shutoff performance.

How to Avoid: Select a Fluidtecq knife gate valve with appropriate gate and seat materials (e.g., hardened steel for abrasives or resilient seats for tight sealing). Ensure the valve’s design, such as a self-cleaning seat or rounded gate, aligns with the media’s properties.

Unlock Optimal Performance with Fluidtecq's Knife Gate Valves: Expert Solutions & Support

Fluidtecq Pneumatics Pvt. Ltd., a leading manufacturer of knife gate valves, offers robust solutions tailored to diverse industrial needs. With their commitment to providing exceptional technical support, Fluidtecq ensures you have all the necessary information for proper valve selection, installation, and maintenance. Contact Fluidtecq today at https://www.fluidtecq.com/ to optimize your KGV applications and avoid these common mistakes.