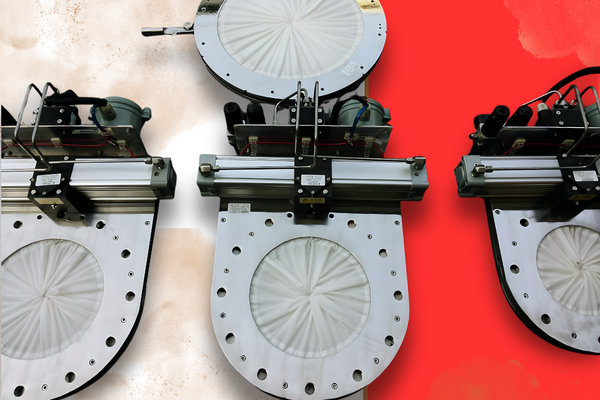

Applications of Fluidtecq Iris Valves in Industrial Processes

Iris valves from Fluidtecq are primarily utilized for the precision handling of dry materials like powders, grains, and pellets. They are a critical component in systems requiring controlled, dust-tight discharge and are frequently used in both coarse and fine filling applications.

Pharmaceutical Industry:

for the sanitary and precise handling of active ingredients and pharmaceutical powders, ensuring no contamination or material damage during discharge.

Food & Dairy Industries:

Ideal for handling fragile food products such as milk powders, sugar, grains, and spices where gentle flow control is essential to maintain product integrity.

Chemical Plants:

Utilized for managing various chemical granules and powders, particularly where dust containment is a priority.

Sugar Industry:

Specifically adapted for Sugar Massecuite applications, featuring rugged construction with metallic fins to handle the unique demands of sugar processing.

Bulk Bag Filling:

used in stations for the controlled filling and discharge of FIBCs (Bulk Bags).

Sanitary ware & Ceramics:

Applied in the handling of raw materials like clay powders and other ceramic granules