Knife Gate Valves for Dry Powder, Slurries, Fly Ash, Pulp & Paper, and High Suspended Solids.

Fluidtecq Knife Gate Valves for Slurries, Fly Ash, Pulp & Paper, Dry Powderand High Suspended Solids.

Key Engineering Feature,Value Proposition to the Engineer Heavy-Duty Construction,Reduced maintenance cycle and lower Total Cost of Ownership (TCO). Customisable Sealing,“Options for resilient, metal, or specialty liners (e.g., PU coated) to achieve zero-leakage, even in abrasive slurries.” Full Port & Non-Clogging Design,“Eliminates media build-up, gate jamming, and flow obstruction.” Actuation Flexibility,“Available in Manual, Pneumatic, Hydraulic, or Motorised configurations to integrate seamlessly into your Industrial Automation architecture.“

Engineered for the Toughest Slurry Powder service

Many valve failures in abrasive service stem from Gate Erosion. FLUIDTECQ addresses this by offering specialized Stellited or Chrome Plated Gates. This hardening solution provides superior surface resistance and a tighter seal than relying solely on soft liners, leading to:

Detailed Technical Specifications & Compliance:

Design Compliance | Design and Tested as per MSS SP 81. Testing Standard: API 598 (Recommended). |

Sizing & Performance | Size Range: 50NB to 900NB (Higher sizes on request). Pressure Rating: Available up to 70 bar (depending on size and class). Service: Ideal for both ON/OFF isolation and Throttling applications. |

Port & Body | Type: Uni-Directional / Bi-Directional Wafer Type Design. Ports: Full Round Port and Square Port availability. Body: Casting & Fabricated Designs. |

Flange Drilling | Complies with ANSI B 16.5 / BS TABLE D, E / JIS / DIN standards, ensuring compatibility with virtually any plant infrastructure. |

MOC Matrix (Material of Construction) | Body: C.I., Carbon Steel (WCB), Stainless Steel (SS304, SS316, SS316L, SS317, Duplex Steel). Gate: SS304, SS316, SS316L, SS317, Stellited, Chrome Plated, SS310 . Seals/Packing: EPDM, Nitrile, Viton, or Gland Packing to suit specific media temperatures and chemical compatibility. |

Technical Features & Specifications

MOCs (Body/Gate) | Body: C.I., Carbon Steel (WCB), Stainless Steel (SS304, SS316, SS316L). Gate: SS304, SS316, SS316L, SS317, Stellited, Chrome Plated, SS310 (for high heat/abrasion). Seals: EPDM, Nitrile, Viton, or Metal-to-Metal. |

Design Compliance | Design Standard: Designed and Tested as per MSS SP 81 . Flange Standard: ANSI B 16.5 / BS Table D, E / JIS / DIN standards available. |

Sizing & Configuration | Size Range: 50NB to 1200NB (Higher sizes on request). Type: Uni-Directional / Bi-Directional, Wafer Type Design. Ports: Full Round Port, Square Port. |

Actuation Options | Manual: Handwheel, Chain Wheel, Gear. Automated: Pneumatic Cylinder (Single/Double Acting), Hydraulic, Electric Actuator. |

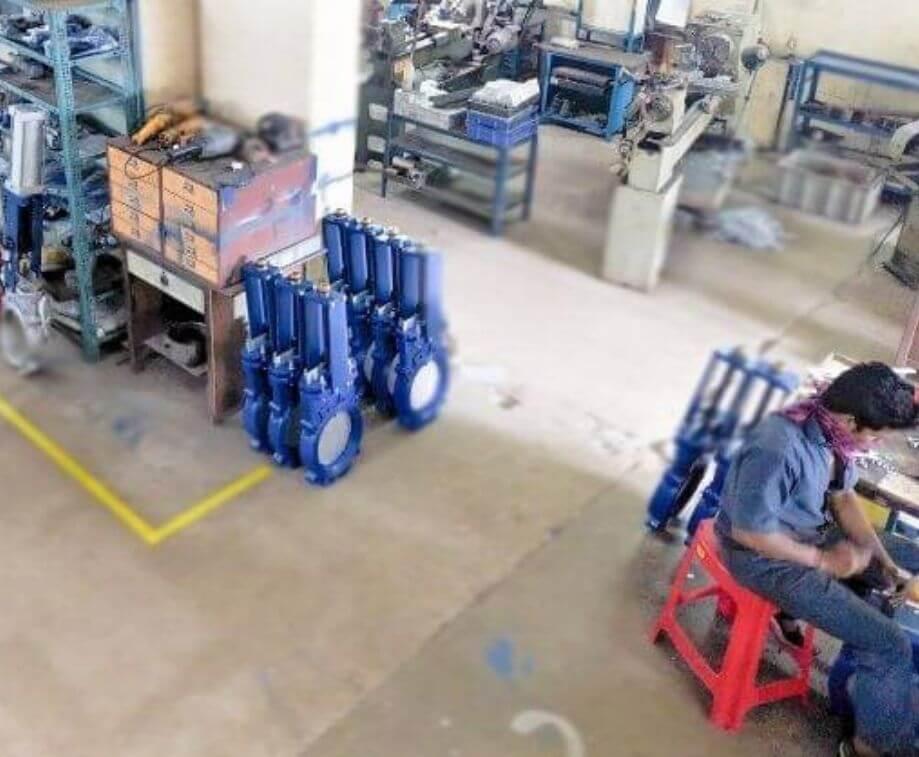

A Trusted Manufacturer with PAN INDIA Support

Our state-of-the-art manufacturing facility and Head Office are located in Ambernath, Thane (Mumbai Metropolitan Region) . We maintain an extensive inventory to ensure fast delivery and support across India, including Pune, Gujarat, Nagpur, and Hyderabad.

Seamless Automation Integration

Actuation Options | Our Knife Gate Valves are available with: Manual: Handwheel, Chain Wheel, Gear. Automated: Pneumatic Cylinder (Single/Double Acting), Hydraulic, or Electric Actuator. |

FLUIDTECQ Automation Advantage | We also manufacture the associated pneumatic control elements, ensuring perfect compatibility and seamless integration: • Solenoid Valves (2/2, 3/2, 4/2, 5/2 Way) • Limit Switch Boxes (General purpose or Flameproof as per IS 2148-1981, Group II A and IIB). |

Why Choose FLUIDTECQ? (35 Years of Excellence)

35+ years of manufacturing expertise. • ISO 9001:2015 certified company. • Dedicated PAN INDIA presence with factory & HO in Ambernath,

Dist: Thane, MH. • Modern machineries ensure best quality and precision engineering.