The Q Factor

Contact us—your questions drive our excellence.

Iris Valves represent a cornerstone of Fluidtecq Pneumatics’ offerings, engineered for precise handling of dry bulk solids such as powders, grains, and pellets. These valves function similarly to a camera’s iris, utilizing a diaphragm that adjusts to regulate material flow with exceptional accuracy. This design ensures efficient control in demanding industrial applications.

**Key Features**:

- **Construction**: Crafted from Aluminum or SS316L (stainless steel), these valves offer durability and corrosion resistance, ideal for industries like food processing, pharmaceuticals, and chemicals.

- **Diaphragm**: Constructed with Nylon or PU-coated Nylon, providing flexibility and strength to manage diverse material consistencies while ensuring a secure seal.

- **Operation**: Available in manual or pneumatic configurations, allowing adaptable functionality based on specific operational requirements.

- **Applications**: Employed in jumbo bag unloading, cleanroom isolation, and metered discharge across sectors such as food, pharmaceuticals, and chemicals.

- **Functionality**: Enables ON-OFF control, coarse or fine filling, and proportionate flow regulation, delivering precision in material dosing.

Iris Valves stand out for their compact design, ease of maintenance, and ability to prevent material leakage, making them suitable for handling sensitive or hazardous substances. Their versatility and robust performance position them as a preferred choice in global markets, reflecting Fluidtecq’s commitment to quality and innovation in flow control solutions.

Fluidtecq Pneumatics serves a broad spectrum of industries, providing precision-engineered solutions that cater to diverse operational requirements. Fluidtecq’s products are designed to handle challenging applications, from bulk material handling to process automation. The key industries served include:

- Food and Pharmaceuticals: Fluidtecq’s valves and automation components are used in processes requiring hygiene and precision, such as powder handling, clean room isolation, and metered discharge.

- Chemicals and Petrochemicals: Fluidtecq’s robust valves and actuators are ideal for handling corrosive materials and ensuring reliable flow control in chemical processing plants.

- Oil and Gas: Fluidtecq’s products support critical applications in exploration, refining, and distribution, where durability and safety are paramount.

- Power Generation: Fluidtecq’s solutions contribute to efficient process control in power plants, ensuring reliable operation in high-pressure environments.

- Mining: Fluidtecq’s valves, particularly Knife Gate Valves, are used for handling abrasive materials in mining operations.

- Pulp and Paper: Fluidtecq’s products support processes like pulp handling and wastewater management in paper manufacturing.

- Water and Wastewater Treatment: Fluidtecq’s valves and automation systems are integral to managing water flow and treatment processes, ensuring efficiency and compliance with environmental standards.

Applications within these industries include pneumatic conveying systems for bulk solids, jumbo bag unloading for efficient material transfer, clean room isolation for contamination-free environments, and process control automation for streamlined operations. Fluidtecq’s ability to deliver tailored solutions ensures the specific needs of each industry are met.

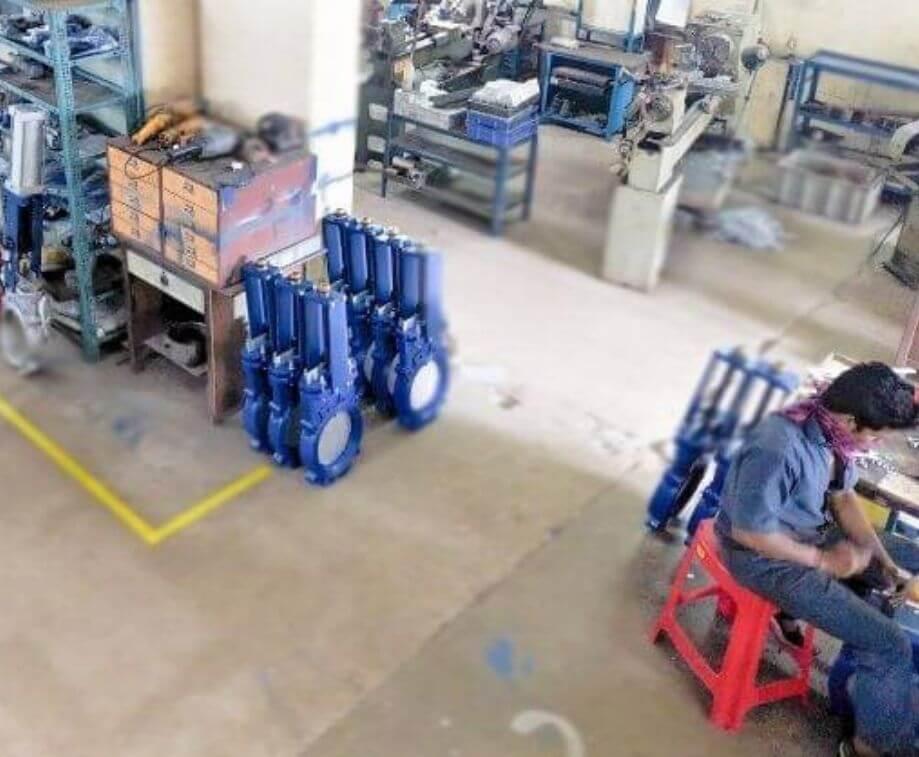

Fluidtecq’s Knife Gate Valves are engineered for demanding applications in pneumatic conveying systems and bulk material handling in India and across the globe. These valves are designed to provide a tight shut-off and reliable performance when handling abrasive or viscous materials, making them a staple in industries such as cement, pharmaceuticals, and chemicals.

Key Highlights:

- Applications: Knife Gate Valves are used in processes involving slurries, powders, and other bulk materials, ensuring smooth flow control and minimal downtime.

- Proven Performance: Over More than 10000 knife gate valves (manual/pneumatic/motorised) have been used by a single client over last 10 years demonstrating their reliability and scalability in large-scale operations.

- Durability: These valves are built to withstand harsh conditions, offering long-term, trouble-free operation even in abrasive environments.

- Design: Engineered for easy maintenance and robust performance, Fluidtecq’s Knife Gate Valves are customized to meet specific operational requirements, ensuring compatibility with existing systems.

Fluidteq Knife Gate Valve's ability to handle challenging materials and maintain consistent performance has made Fluidtecq’s Knife Gate Valves a trusted choice for industries requiring dependable flow control solutions.

Our Approach to Sustainability at Fluidtecq Pneumatics we demonstrate a commitment to sustainability through the design and manufacture of durable, efficient flow control and automation products, including Iris Valves, Knife Gate Valves, Solenoid Valves, and Pneumatic Actuators. By using high-quality materials like Aluminum, SS316L stainless steel, and PU-coated Nylon diaphragms, we ensure our products deliver long-term reliability, reducing the need for frequent replacements and minimizing material waste. For instance, we have installed More than 10000 knife gate valves (manual/pneumatic/motorised) have been used by a single client over last 10 years and clients like Raj Process Equipment have relied on our valves for over 15 years, showcasing exceptional durability. Our customized solutions, developed by an in-house R&D team, optimize industrial processes such as jumbo bag unloading and metered discharge, enhancing resource efficiency and reducing material and energy waste in industries like food, pharmaceuticals, and water treatment. We also support environmentally sensitive applications, such as wastewater treatment, where our precise flow control solutions ensure compliance with environmental standards. Additionally, our robust after-sales support, with dedicated service teams in India and abroad, extends product lifespans, further reducing environmental impact. For more details on our sustainability practices, visit our official webpage at www.fluidtecq.com.

Fluidtecq’s technology integration services enhance customer operations by leveraging years of in-depth knowledge and a dynamic, never-give-up approach to develop solutions tailored to client requirements. This boosts efficiency, reduces downtime, and ensures precision for industries like Foods, Dairy, Cement, Chemical, Pharmaceutical, Oil & Gas, Oil & Gas Waste Water Treatment, and Power. Customized solutions optimize performance, improve scalability, and align with ISO 9001:2015 standards, delivering cost-effective, reliable outcomes.

The “Q” in Fluidtecq Pneumatics Private Limited stands for Quality, Quick Response, and a relentless Quest for Innovation.

Since its establishment in Thane, Maharashtra, in 1989, Fluidtecq has embodied these principles, becoming a trusted leader in the valve and automation industry. With a comprehensive portfolio of Knife Gate Valves (KGVs), Ball Valves, Butterfly Valves, and Pneumatic Automation Systems, Fluidtecq delivers tailored, high-performance solutions for industries like food processing, wastewater treatment, mining, and pulp and paper.

Here’s how the Q Factor—Quality, Quick Response, and Quest for Innovation—gives Fluidtecq and its products a competitive edge:

1. Quality: Comprehensive Product Portfolio for Diverse Applications

Fluidtecq’s commitment to quality is reflected in its versatile product range, designed to meet the unique demands of various industries:

- Knife Gate Valves (KGVs): Engineered for challenging applications, KGVs feature V-notch and O-port designs and 100% leak-tight sealing (Class VI for resilient seated valves), excelling in handling viscous fluids, slurries, and fibrous materials. Over 10,000 KGVs supplied to food processing companies in the last decade demonstrate their reliability and client trust.

- Ball Valves: Built for precision shut-off and low-torque operation, these valves are ideal for high-pressure and high-temperature applications in chemicals and oil & gas.

- Butterfly Valves: Offering efficient flow control with low-pressure drop and compact designs, they suit water treatment, HVAC, and food processing applications requiring minimal maintenance.

- Pneumatic Automation Systems: From air cylinders to actuators, these systems ensure seamless integration and precise control, boosting productivity in automated processes.

This high-quality portfolio ensures Fluidtecq delivers reliable, industry-specific solutions with unmatched performance.

2. Quality: In-House Manufacturing Excellence

Fluidtecq’s state-of-the-art facility in Thane ensures uncompromised quality through:

- In-House Component Production: Critical components like air cylinders, valve bodies, and actuators are manufactured internally, ensuring consistent quality and customization.

- Rigorous Testing: All products meet stringent standards, such as MSS SP 81:2013 for KGVs, guaranteeing durability and performance.

- Custom Solutions: In-house capabilities allow tailored designs (e.g., valve sizes from 3" to 22" or beyond), ensuring precision and faster delivery.

3. Quest for Innovation: Advanced Automation for Efficiency

Fluidtecq’s innovative automation solutions set its products apart:

- Versatile Actuation Options: Pneumatic (double-acting and single-acting with fail-safe) and motorized actuators with manual overrides ensure compatibility with automated systems.

- Precision Control: Features like positioners for proportionate control in KGVs and Ball Valves enhance accuracy in complex processes, critical for food processing and wastewater management.

- Seamless Integration: Pneumatic Automation Systems are designed for effortless integration, minimizing downtime and maximizing productivity.

4. Quality: Durability and Low Maintenance

Fluidtecq’s products are built for longevity in demanding environments:

- Robust Construction: KGVs feature sand-blasted, epoxy-painted bodies and protective bellows/gaiters, while Ball and Butterfly Valves use corrosion-resistant stainless steel.

- Minimal Maintenance: High-performance designs reduce operational costs, with KGVs driving repeat orders from food processing clients due to their durability.

- Industry-Specific Solutions: Food-grade materials ensure hygiene for KGVs and Butterfly Valves, while Ball Valves handle high-pressure environments, offering versatile reliability.

5. Quick Response: Exceptional After-Sales Support

Fluidtecq’s quick and responsive after-sales support is a cornerstone of its competitive edge:

- Prompt Technical Assistance: A dedicated team provides troubleshooting and maintenance support, ensuring uninterrupted operations and minimal downtime.

- Spare Parts Availability: In-house manufacturing guarantees a steady supply of spare parts for all products, enabling fast replacements and repairs.

- On-Site and Remote Support: Clients benefit from installation guidance, training, and remote consultation, ensuring optimal product performance throughout their lifecycle.

- Long-Term Partnership: This responsive support fosters trust, contributing to the loyalty of food processing clients who have returned for over 10,000 KGVs in the past decade.

6. Quest for Innovation: Customer-Centric Approach and Proven Loyalty

Fluidtecq’s innovative, client-focused approach drives its success:

- Tailored Solutions: Custom valve designs and automation systems address specific challenges, such as handling powders, granules, or high-pressure fluids.

- End-to-End Support: From design consultation to implementation, Fluidtecq’s engineering team ensures seamless project execution.

- Client Trust: The supply of over 10,000 KGVs to food processing companies, with consistent repeat business, reflects Fluidtecq’s ability to deliver reliable, innovative solutions.

7. Quality: Versatility Across Industries

Fluidtecq’s product range serves a broad array of sectors:

- Food Processing: Hygienic KGVs and Butterfly Valves ensure contamination-free operations with food-grade materials meeting strict regulatory standards.

- Wastewater and Mining: Robust KGVs and Ball Valves handle abrasive slurries and high-pressure conditions.

- Pulp and Paper: Specialized KGVs manage fibrous materials efficiently.

- Chemicals and Oil & Gas: High-performance Ball Valves and automation systems ensure safety and precision.

This versatility makes Fluidtecq a one-stop solution for diverse industrial needs.

8. Quest for Innovation: Legacy of Excellence Since 1989

Fluidtecq’s relentless pursuit of innovation defines its legacy:

- Continuous R&D: Investment in cutting-edge technology keeps KGVs, Ball Valves, and automation systems at the forefront of performance and efficiency.

- ISO 9001:2008 Certification: Reflects Fluidtecq’s commitment to quality and process excellence.

- Global Reach: A reputation for reliability enables Fluidtecq to serve clients worldwide, backed by over three decades of innovation and customer satisfaction.

The Q Factor Advantage

The Q Factor—Quality, Quick Response, and Quest for Innovation—defines Fluidtecq’s competitive edge. With a diverse, high-quality product range, in-house manufacturing, advanced automation, exceptional after-sales support, and a customer-centric approach, Fluidtecq delivers solutions that combine durability, precision, and innovation. From Knife Gate Valves earning loyalty in food processing to Ball Valves, Butterfly Valves, and Pneumatic Automation Systems serving global industries, Fluidtecq sets the standard for excellence in the valve and automation industry.

For more details on Fluidtecq’s products and services visit our website

-

Unleash the Power of Q with Fluidtecq!

It’s the ‘Q’ in Fluidtecq—our mark of Quick response, Quantum precision, Quality engineering, and a Quest for innovation.

The "Q" in Fluidtecq stands for Quality, Quest, and Query-driven innovation. It reflects our commitment to delivering high-performance valve and automation solutions with uncompromising quality, a continuous quest for improvement, and a customer-first approach that thrives on solving real industrial challenges.

Fluidtecq Pneumatics Pvt. Ltd., is a leading manufacturer and exporter of high-quality flow control and automation products designed to meet the demands of various industrial applications with a diverse product portfolio we cater to industries requiring precision-engineered solutions for process automation and material handling. The key product categories include:

- Industrial Valves: Fluidtecq produces a wide range of valves, including Iris Valves, Knife Gate Valves, Butterfly Valves, Ball Valves, Auto Drain Valves, Dampers, and other specialized valves. These valves are engineered for durability, precision, and versatility, making them suitable for handling fluids, gases, and bulk solids in industries such as oil and gas, water purification, power, coal, sugar factories, conveying, packaging, food processing, dairies, pharmaceuticals, and chemicals.

- Valve Automation: This category includes Solenoid Valves, Pneumatic Actuators, and Pneumatic Cylinders. These components are designed to enhance automation by providing reliable and efficient control over valve operations, ensuring seamless integration into automated systems for consistent performance.

- Project Solutions: Fluidtecq offers custom-engineered pneumatic and instrumentation products tailored to specific industrial needs. These solutions are developed through close collaboration with clients to address unique challenges, ensuring optimized performance in applications like pneumatic conveying, process control, and cleanroom isolation.

Fluidtecq’s products are known for robust construction, adherence to international quality standards, and ability to perform in demanding environments. Their focus on innovation and customization makes them a trusted partner for industries worldwide. *Click here to know more.*

Yes, Fluidtecq specializes in providing customized solutions to address industry-specific challenges. Our in-house Research and Development (R&D) team works closely with clients to design and manufacture products that meet unique operational requirements.

Key aspects of their customization capabilities include:

- Tailor-Made Solutions: Fluidtecq develops bespoke products, such as customized Iris Valves, Knife Gate Valves, Butterfly Valves, Ball Valves, Pneumatic Valves, Actuators, and other components, to suit specific process conditions.

- System Integration: Our solutions are designed to seamlessly integrate with existing equipment, ensuring minimal disruption and maximum efficiency.

- Industry-Specific Design: Whether it’s handling abrasive materials in mining or ensuring hygienic conditions in pharmaceuticals, Fluidtecq’s products are engineered to meet the precise needs of each industry.

This focus on customization, combined with our engineering expertise, allows us to deliver solutions that enhance productivity and operational reliability.

Fluidtecq Pneumatics stays ahead by blending the wisdom of its founders with the innovative drive of the younger generation.

Our team actively monitors industry developments through continuous research, leveraging advanced technologies like AI and IoT to enhance product design and performance. We engage with industry forums, adopt best practices, and integrate cutting-edge automation to ensure our valves and actuators meet evolving standards in Foods, Chemical, Pharmaceutical, Oil & Gas, and other sectors.

Fluidtecq Pneumatics carefully manages consultancy services by aligning project scope with client needs, ensuring efficient resource allocation. We employ a client-centric approach, tailoring solutions for industries like Foods, Chemical, Cement, Oil & Gas Water, and Pharmaceuticals etc. with a focus on delivering measurable outcomes. Our ISO 9001:2015 framework ensures consistent quality, while our team optimizes service volume through strategic planning and technology-driven insights

.

Follow-Up Support

Want to know more?

Fluidtecq Pneumatics FAQ At Fluidtecq Pneumatics, the “Q” in our name stands for Quality, Quest, and Query-driven solutions. This FAQ section addresses common questions about our solenoid valves, industrial valves, and pneumatic actuators—from product features and selection guidance to installation, maintenance, and customization options. As an ISO 9001:2015-certified company, we ensure that every product meets rigorous quality standards and is built for performance and durability. Learn more about how our valves integrate into your industrial systems, our fast order fulfillment processes, and how we tailor solutions to your specific needs. Your queries inspire us to deliver smarter, more reliable flow control solutions—every time.