- W-97, MIDC, Anand Nagar, Ambernath (E), Dist: Thane, MH, INDIA, Pin: 421506

- marketing@fluidtecq.com

How Air Blasters Solve Cement Challenges

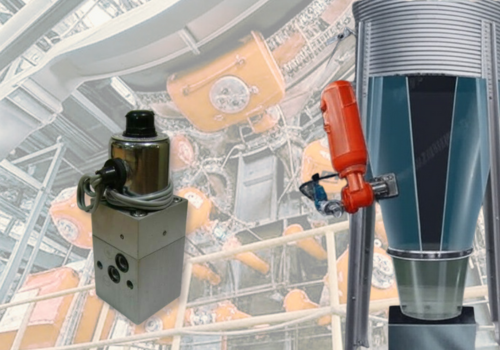

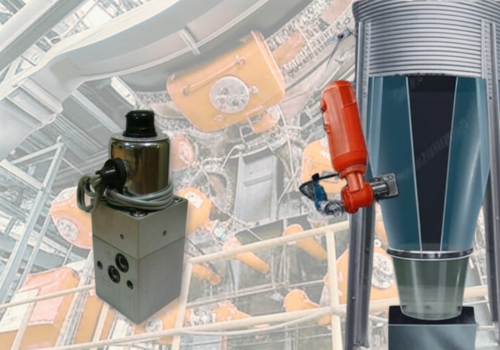

Air blasters use high-pressure air bursts to dislodge materials like powders, granules, and clinker. Fluidtecq’s solenoid-operated valves are the heart of these systems, enabling:

- Storage: Compressed air is held in a receiver.

- Release: Rapid valve actuation via Q-point design delivers controlled bursts with minimal delay.

- Action: Shockwaves clear blockages, restoring flow.

Our valves are engineered for critical cement applications:

- Pre-Heater Towers: Prevent arching and buildup for consistent material feed.

- Silos and Hoppers: Break bridges and ratholes to ensure smooth discharge.

- Ducts and Chutes: Clear clogs in transfer systems and grates.

- Process Equipment: Remove adhered materials to maintain production.

- For OEMs: Our valves are designed for high-volume air cannons, with advanced nozzle compatibility for superior reach. NAMUR-mount options and materials like aluminum or stainless steel ensure seamless integration, boosted by the Q-point advantage for efficient response.

- For Cement Plants: As replacements, our valves reduce downtime by up to 50%, cut maintenance costs by 30%, and enhance safety by minimizing manual interventions, all powered by Q-point precision.

Choose the right valve by considering:

- Vessel Size: Match valve capacity to equipment volume.

- Material Characteristics: Address the stickiness or flow behavior of cement materials.

- Operating Conditions: Opt for dust-resistant, weatherproof (IP-67/IP-68) valves for harsh environments.

- Cannon Design: Select valves supporting advanced nozzles for maximum cleaning efficiency, enhanced by Q-point actuation.

- Pressure Range: 1-10 bar (custom up to 300 bar).

- Materials: Durable for gases, chemicals, and vacuums.

- Certifications: Flameproof (IS 2148), IP-67/68, approved by CMRS Dhanbad and COE Nagpur.

- Q-Point Advantage: Ensures quick, energy-efficient valve operation for reliable shockwave delivery.

Fluidtecq is powering local manufacturing from our Thane, India hub. Through #MakeInIndia and #IndiaMakesWithFluidtecq, we ensure:

Following recent tariff impositions, Fluidtecq is leading with our #MakeInIndia initiative from our Thane, India manufacturing hub. #IndiaMakesWithFluidtecq focuses on localized production of Air Blaster Pneumatic Valves, offering OEMs and cement industries faster access, reduced costs, and supply chain security—empowering India's industrial self-reliance.

A cement plant using Fluidtecq valves reported 60% fewer blockages in hoppers, boosting throughput. OEM partners praise our valves for easy integration and reliable performance in global projects, further strengthened by our local manufacturing push.

As the leading manufacturer, we produce valves in-house at our Thane, India facility, ensuring quality and fast global delivery. Contact sales@fluidtecqpneumatic.com for samples or technical consultations.

Fluidtecq’s Air Blaster Pneumatic Valves are the industry standard for cement plants and OEMs, with Q-point advantage and our #MakeInIndia commitment driving efficiency. Clear blockages, reduce costs, and enhance safety with our proven solutions. Visit our product page to learn more!